SPECIFICATIONS

Manufacture

- Kampf

- Model RKW-1003

- New 2001

Entry Strip Width

- 25" min to 69" max (635 - 1753mm)

Strip Thickness

- .002 - .015" (0.05 - 0.381mm)

- NOTE: Kampf says that with minor knife modifications this line can run a) .037" / 0.93mm Can Lid Stock; and b) O temper, dead soft aluminum at .081" / 2.06mm

Line Speed

- 2600 fpm max (800 mpm)

- Depends on material type, thickness, spool, etc.

Material Processed

- Aluminum

- Alloys: 1145, 1100, 3003, 7072, 8111

- Temper: O thru H19

EQUIPMENT

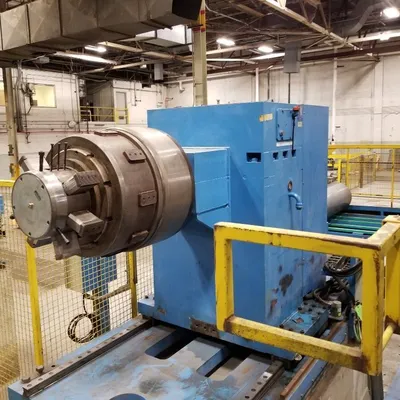

Unwind Reels

- Coil ID (Spool Sizes)

a. 23.75" x 26" x 72" (603 x 660 x 1829 mm)

b. 12.812" x 16" x 66" (325 x 406 x 1676 mm)

c. 12" x 16" x 27.50" (304,8 x 406 x 698,5 mm)

Note - stands are designed to allow future spool length of 76" (1930mm)

- Coil OD = 24" min, 90" max (610mm min, 2286mm max)

Recoiler Reels

- Cuts = 40 cuts max + edge trim

- Cut widths = 0.6" - 46" (15.8 mm - 1169 mm)

- ID min = 18" (457mm)

- OD max = 72" (1829 mm)

- Spool ID = 6, 10, 12, 16" (152, 254, 304, 406 mm), cardboard fiber spools

Slitting System

- Scissors cut design

Edge Trim

- 0.5" min - 2.0" max each side (12.7 - 50.8 mm each side)

- Slit width tolerance = +/- 0.1 mm

- Jogging speed approx. = 10 m/min. (adjustable)

- Acceleration / deceleration = VO-V max. = approx. 80 seconds

- Instantaneous stop = V max-VO = approx. 40 seconds

- Emergency stop = V max-VO = approx. 10 seconds

- Winding tension/unwind = 12.650 N max

- Winding tension/rewind 1 = 318 - 6328 N, 25% Taper Tension at outer diameter

- Winding tension/rewind 2 = 318 - 8438 N, 25% Taper Tension at outer diameter

Elongation unit (stretcher)

- Capability = 1.5 - 3.0% with a target of 2.0%

- Machine design = drive side on the right as seen in material running direction.

Power:

- Voltage = 480 volts / 3 ph / 60 Hz

- Control voltage = 24 volts

- Total supply value = approx. 700 kva

Air:

- Continuous pressure = >/- 5,5 bar >/- 77 psi

- Consumption approx. - 24 nm3/h

Water:

- Flow = 1,5 m3/hr (53 cu ft/hr)

Main Machine:

- Drive side on the right

- Unwind with stepped expanding heads

- Stretch stand

- Two slitting cassettes

- Pusher plates on rewinds

- Drives, motors and SPS from siemens

Siemens programming unit with modem and programs

Winding shafts:

- 2 rewind shafts 6"

- 2 rewind shafts 10"

- 2 rewind shafts 12"

- 2 rewind shafts 16"

Entry Side Coil Handling Equipment

- Coil car with fixed saddle

- Spool roller table with spool deposit

- Two coil deposit stand non-driven (spools 66", 72", 76")

- Empty spool roller table with spool deposit

Exit Side Coil Handling

- 2 transport cars

Edge trim material handling

- Suction, chopper, transport chutes, air-separator, diverter gate, vacuum hose and maintenance platform.

Sold "as is, where is" FCA Ohio, USA warehouse

We use cookies to improve your experience. Privacy Policy.