Manufacture:

- ALTEK

- New: 1974

- Modernized: 2010

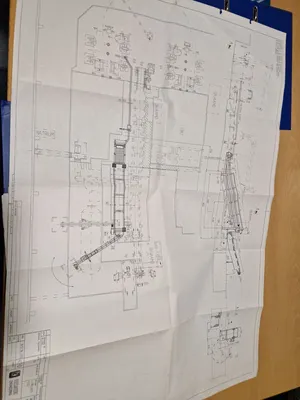

Scope:

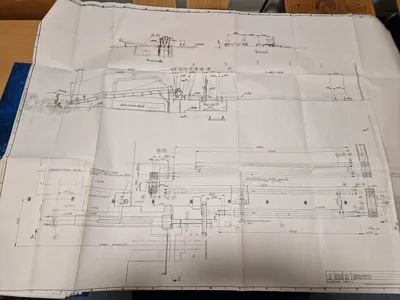

- Reverb furnaces/ caster conveyors / auto conveyor to stacker / robotic stacker

Products:

- 7.0kg ingot = RSI (remelt secondary ingot)(CuSiAl)

- DeOx Cone = 98% Al

Capacity:

- 7.0kg Ingot = 7.5mton/hr production (18 ingots/min x 7.0kg)

- DeOx cone: 2.5mtons/hr production

Equipment:

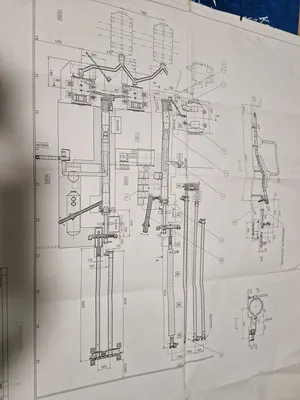

Casters:

- Two (2)

- Each caster has two conveyors with ingot molds and de-ox cone molds

Holding Furnaces:

- 15mton / 27mton / 30mton

- For holding/alloying molten metal

Burners:

- Manufacturer = AGA

- Type = Oxyfuel

- Power output = 3 x 1.5MW

- Fuel = light or heavy fuel oil

Cooling Section:

- water quench

Automated Finishing conveyor

Robotic Palletizer:

- recently installed, automated, laying 5 ingots per row

Notes:

- Flexible capabilities regarding both products and raw material inputs

- Combining multiple sources of recycled input to a wide range of products

- Fully operational and well-maintained

- Integrated set up including smelting, casting, filtering and supporting systems. Upstream integrated sink and float process

- Annual revenue = approx. EUR 60-75 million

- Typical production = 40,000 mtons (ingot and cone)

Sold "as is, where is" EXW on foundation, Europe.

We use cookies to improve your experience. Privacy Policy.